We have always had oil cooling issues. For the most part we could live with it - but historically when we would climb up to 5500’ two-up in the summer that was as high as we could go, because the oil would be approaching 230. Once we leveled off, the oil temp would come down slowly and be fine in cruise. When I would fly solo to 6000’, I would often see 220F but it would cool down once I started doing maneuvers. Especially because I’d have to pull the throttle back during dives to keep the engine from overspeeding.

Recently we rebuilt the engine, and one of the things I discovered was the oil cooler seemed to have some blockage. When I used the bypass that came in my kit, or when I put on a new cooler, the oil pressure dropped from 70 in cruise to 50, which is where it should be. We polished up the bypass piston, added a supplemental spring, and were convinced from doing the math that the system should not go into bypass, meaning not flow through the cooler, except for a cold start where the pressure could spike to 80-90 PSI. But even with the new cooler, we still had high temps, in fact worse than before. Partly this was because we have been evil and have been hot-rodding our AeroVee. We bumped compression to 9:1, added 1.25:1 ratio rockers, plus as I documented on the old forum I added fresh air induction and GPAS cast manifolds that were nicely ported and polished. I did a lot of baffle work, documented on this forum, to keep CHTs in check. But though the CHTs were good, the oil was hot. A solo climb to 6000’ to do aerobatics would push me over 230. 2-up we would struggle to get over 3500’ because we would approach 230. The oil was just too hot. My thought was the extra heat from the extra performance was getting taken out of the heads. but the pistons would also see that increased heat and they transfer most of it to the oil.

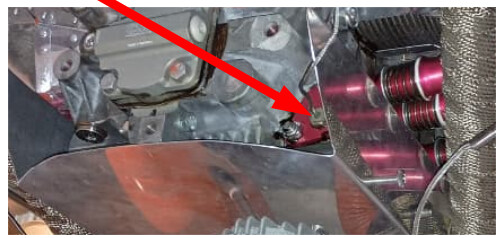

I had to do something. I didn’t want to give up the performance. A Jabiru 3300, though desirable, would be for another day maybe. What I did was to fabricate and install a sump baffle like the bottom mount oil cooler guys use.

This was a fairly easy part to make on the brake although it took me 3 iterations to get all the hole locations correct.

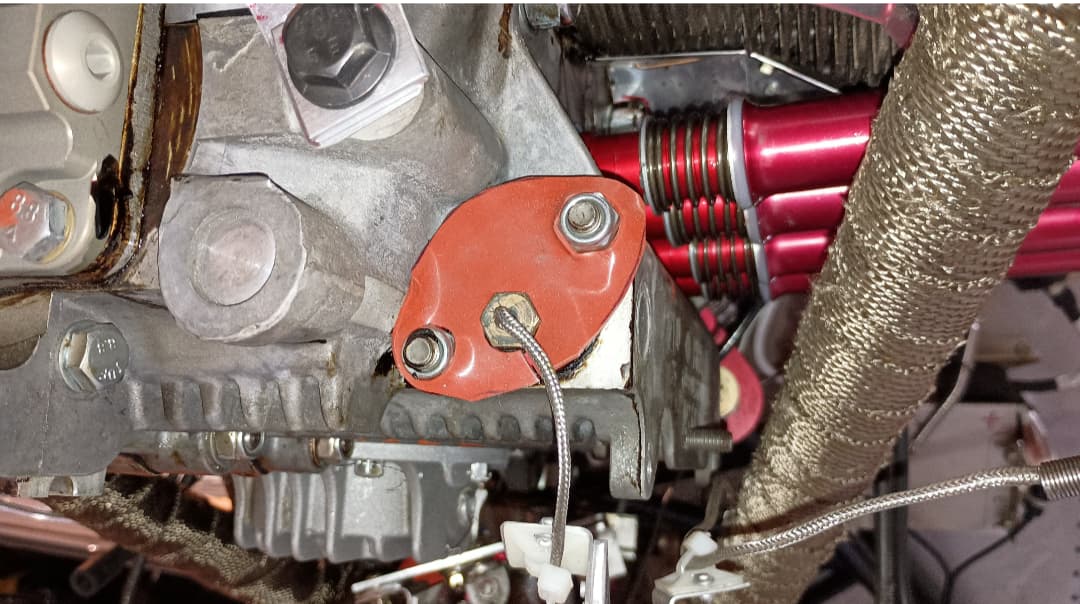

Here is the top closeout after putting the seal on the front. It’s a good view of the complicated pattern to get a good fit.

Here is the new baffle installed, ready for cowl installation:

The AeroVee manual calls for a slot approximately 5” wide, 2” tall, and cut 5” below the cowl prop opening. I made mine only 1” tall, and I had to move it up an inch to 4”. My baffle is not as deep as a standard sump baffle.

And now onto the results. This morning I climbed to 6500’, oil temperature peaked at 197F and came down to 180F in cruise. I was worried that this air going in to the lower cowl might affect my CHTs, but my peak CHT was 315F. Adam has since flown 1.8 hours today in the Waiex and also reports good temperatures.

I’m not sure if the top mounted oil cooler is insufficient given my modifications, or if the air flow through it is not enough. But with the addition of sump cooling, I’m good.