After the last time we put the heads on, we had a pretty good oil leak on the #3 exhaust pushrod tube. That was really sad, because it seemed we fixed our other leaks. I went and bought a couple different ones - the EMPI threaded tubes with the jam nut and the CB Performance spring loaded Pro-Series tubes. One of my favorite VW reference guys from Area51 suggested the spring loaded tubes, so I went with that. You need to remove the rocker shafts, and the pushrod, and cut the old tube in half. Stomp on it a couple times and throw it in the trash.

In this picture, I think it is backwards. It was easier to put in this way, and for our stock motors it really doesn’t matter. If you have a big cam bug or higher than stock ratio rockers (subtle foreshadowing) it should go the other way to maximize clearance between the pushrod and tube.

But before I could get to this picture, I had to hack some clearance into the super tin. That was really a pain on the engine, given there is not much room and also open holes to the engine.

Lo and behold, no more oil leak on the #3E tube. Unicorns leaping and angels singing. So, I was sold. I ordered up a set of 8 in AeroConversions red, and put them in. Note that these are installed correctly if I ever wanted to hot rod things up (subtle foreshadowing).

The plus of replacing all of them, instead of just one, is you can remove the super tin and do the hacking off the motor. It ends up being a lot of hacking. If you intend to keep everything stock, there are a few other spring loaded options which are smaller and would probably not require this. CBP offers smaller tubes and I know of another builder who used SCAT tubes.

Better yet, you could fabricate optimized aluminum baffles with better clearance.

https://backup.sonexpilots.org/t/baffle-optomizations/4003

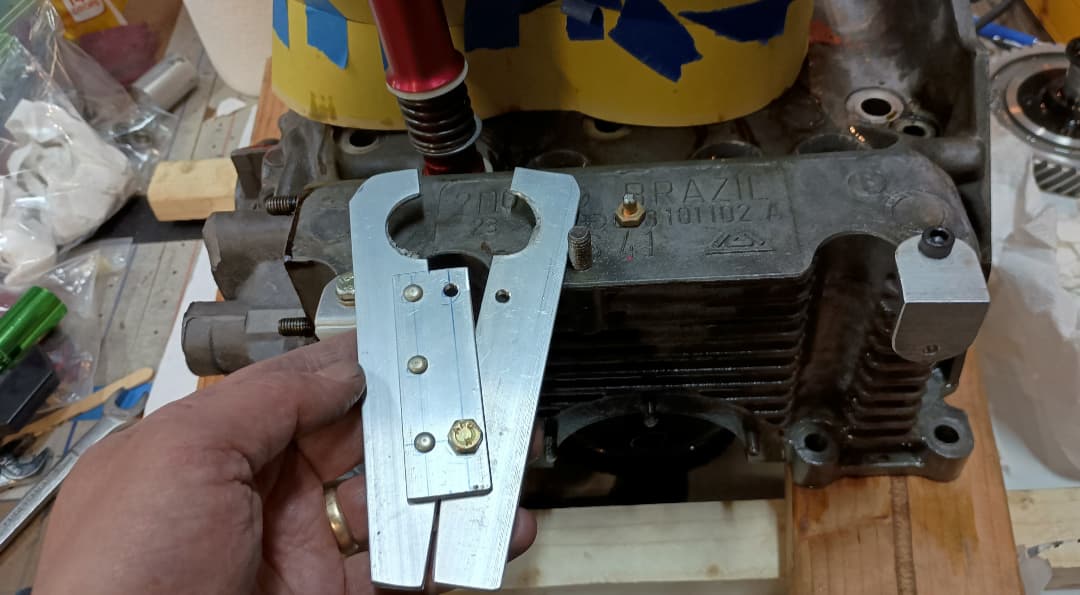

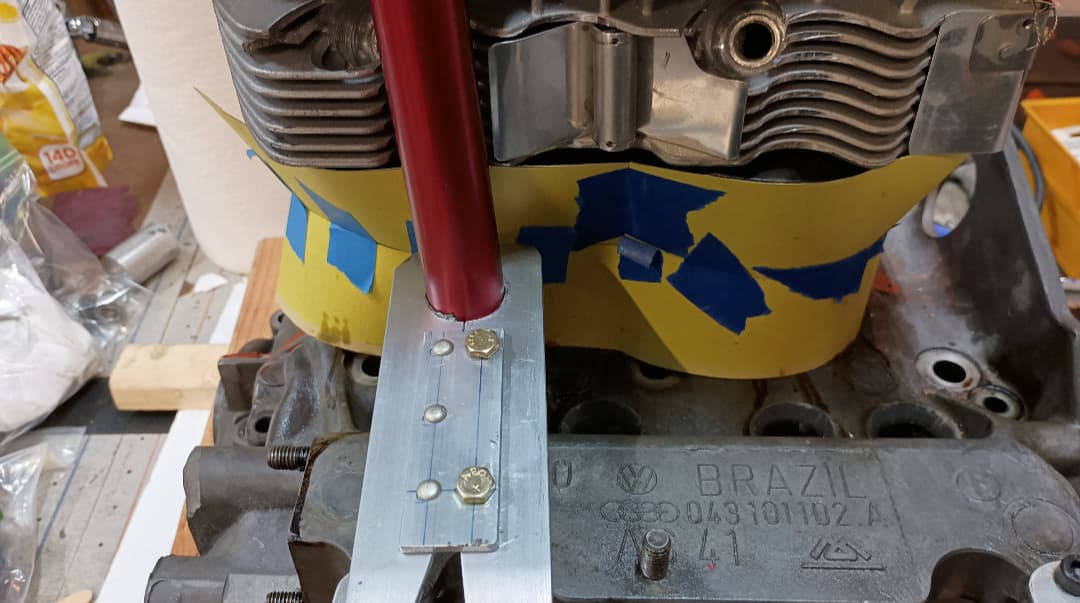

When I did the new baffles I had the motor apart due to the power steering pump making a bad whine, which is bad because we don’t have a power steering pump. That’s a post for later. But I had the tubes in and out a lot. I had some restrictions due to cataract surgery (Yay!) and needed an easier way to compress the tubes for installation. The challenge is they are always oily and when you install them the right way there is not much to push on - just a flare near the bottom. So I made this tool:

I used a 1" holesaw which is the OD of the tube. Then on the bottom I chamfered it a little so it would rest nicely on the flare of the tube, and lined it with the good duct tape.

This tool makes it super easy. Not sure how easy or hard the other spring loaded tubes are to install, but a similar tool could be made.

What I like about this design is it holds a constant pressure. For the stock tubes you have to stretch them out to reuse them, and I know people do it, but they must secretly be T800 terminators or have made special tooling.