EMPI Full-Flow High Volume Oil Pump and Filter unit

Posted: Fri Dec 01, 2023 3:52 pm

by Hap Hazard

Hi Guys and Gals,

New to the forum, however I am getting to know my Aerovee engine which was fitted to the Onex I recently brought. Looking at the oil-pump fitted to the engine, it has 26mm oil pump gears, which I assume is a standard size to Sonex?

I am looking to fit an oil filter but want to avoid unnecessary connectors and pipes with a piped external filter, which introduces possible failure points. I hear that the all-in-one EMPI style pump/filters dont give as good as flow as the remote style by-pass systems that often requires the case being drilled, however the higher capacity 30 mm units should help overcome any real reduction of flow rates with a standard size pump.

Has anyone out there fitted a 30mm gear high-volume EMPI style all-in-one adaptor to their engine and have you had any observed issues with it? Indeed, is there room to fit one in behind a Onex cowling?

BTW, I am aware of the mini-sump kits, but do not like the idea of “drawing” oil through a filter…

Regards,

HH

Re: EMPI Full-Flow High Volume Oil Pump and Filter unit

Posted: Fri Dec 01, 2023 5:03 pm

by Area 51%

I did have one on my first Waiex, and will have it again on my next.

I did have to cut a relief in the front of the cowl. At this time, I don’t remember the part number, but there is a shorter filter that doesn’t take up as much space. Didn’t form a blister over it. Just let the filter, more or less, plug the hole. It also has the benefit of acting as an oil cooler. I had to block off a portion of the top mounted cooler to get the temp up.

I also had the mini sump. Not for the filter, but to increase the oil capacity. Just leave out the filter and make sure the pick-up goes lower.

Re: EMPI Full-Flow High Volume Oil Pump and Filter unit

Posted: Fri Dec 01, 2023 5:03 pm

by Bryan Cotton

I had a remote filter and removed it. Saved 2.5 lbs. Also eliminated issues with the filter blowing out on startup when the oil is cold. I would think carefully before you add something you don’t really need. Also regarding adding flow with a 30mm pump - why?

There is no way that would fit behind my Waiex cowl.

Re: EMPI Full-Flow High Volume Oil Pump and Filter unit

Posted: Fri Dec 01, 2023 7:12 pm

by tps8903

Hap Hazard wrote:Hi Guys and Gals,

New to the forum, however I am getting to know my Aerovee engine which was fitted to the Onex I recently brought. Looking at the oil-pump fitted to the engine, it has 26mm oil pump gears, which I assume is a standard size to Sonex?

I am looking to fit an oil filter but want to avoid unnecessary connectors and pipes with a piped external filter, which introduces possible failure points. I hear that the all-in-one EMPI style pump/filters dont give as good as flow as the remote style by-pass systems that often requires the case being drilled, however the higher capacity 30 mm units should help overcome any real reduction of flow rates with a standard size pump.

Has anyone out there fitted a 30mm gear high-volume EMPI style all-in-one adaptor to their engine and have you had any observed issues with it? Indeed, is there room to fit one in behind a Onex cowling?

BTW, I am aware of the mini-sump kits, but do not like the idea of “drawing” oil through a filter…

Regards,

HH

I don’t think it’ll fit under the cowl. Aerovee has a parts list for a remote oil filter for rhe Turbo. You might be able to adapt that for a standard Aerovee if you are so inclined.

Plenty of certified aircraft engines operate without modern day filtration. The oil change intervals are less to reflect that. Aerovee is 25 hours, so I believe that’s why they don’t bother with the added complexity of a filter. It became a requirement for a filter on the turbo due to fine particulate siezing the shift bearing.

Re: EMPI Full-Flow High Volume Oil Pump and Filter unit

Posted: Sat Dec 02, 2023 2:16 am

by karmarepair

My teacher (“Veeduber”) did not like them.

The stock oil pump has cast iron body and a cast iron cover. They NEVER wear out. Whatever (minor) thrust the oil pump gears exert gets reacted across the whole face of both gears on the IRON pump cover.

Full flow the case, and you have cut a hole in this reaction surface on the pump cover to let the oil out to go to a filter and/or a cooler. Plus, MOST full flow pump covers are pot metal. Less surface area, and a softer substrate => the pump cover wears out.

The pump/filters compound this; there are TWO holes on the surface the pump gears bear on now, and still the pump cover is pot metal.

If you want a filter, Gene Berg sells STEEL pump covers with oil outlets. You can even get them with relief valves so that if the oil is cold and/or the oil relief piston sticks in it’s bore, it won’t blow up the “stock” filter. There is plenty of room on the engine mount to hang a remote filter mount. https://photos.app.goo.gl/vstt1LXFRFL1vFvP6 Ivan Schultz’s AeroVee installation. Notice the FRAM HP filter - no relief on his pump cover. I’d use a shorter HP18, me, but I’m running my AeroVee without a filter right now TO GET THIS AIRPLANE FLYING!

Re: EMPI Full-Flow High Volume Oil Pump and Filter unit

Posted: Sat Dec 02, 2023 9:17 am

by Area 51%

karmarepair wrote:The stock oil pump has cast iron body and a cast iron cover.

Actually, it’s a stamped steel cover. But point taken.

You will find more damage to the pump gears, resulting in a potential drop in pressure, due to incoming debris from the suction side than can be expected from pump cover wear. Enter the filter in the Mini-Sump. (Works very well with hot oil.) .

However, it would be hard to find a better lubricated component inside an engine than the oil pump. Add to that the fact there are multiple soft-to-hard interactions within an engine (bearings-to-crankshaft springs to mind) and the longevity of an oil pump cover seems trivial. Change it at teardown if it makes you nervous.

I have had one of these pump/filter assemblies on my buggy for 10 years and 85k miles. I check it every other year and so far you can barely feel a step where the pump gears ride. It takes a sensitive fingernail indeed. The “wear” pattern on the unit I had installed on my Aeroveeish of 80hrs indicates it too would have had no problem making the run to overhaul.

My recommendation is to use whatever helps you sleep at night. .

Re: EMPI Full-Flow High Volume Oil Pump and Filter unit

Posted: Sat Dec 02, 2023 12:04 pm

by Bryan Cotton

Area 51% wrote:My recommendation is to use whatever helps you sleep at night.

That’s a keeper!

I do have a Gene Berg pressure relief valve cover. I figured since I removed the weak link of the filter seal, the oil cooler would be the next fuse in the system. I’d really like to remake the cover out of aluminum. It’s heavy.

Re: EMPI Full-Flow High Volume Oil Pump and Filter unit

Posted: Sat Dec 02, 2023 4:14 pm

by Hap Hazard

Thanks guys for the answers to date. Pretty predictable spread out there on opinion, either side of the argument (depending on your view of course).

Firstly, my opinion is exactly that, (like yours) my opinion and I am obviously not an automotive design engineer, nor do I believe I know more than the guys at Sonex…

Firstly Karmarepair, thanks for the reply which introduces something that I hadnt really thought too much about in terms of wear. Most of the aftermarket pump covers I have seen on suppliers website are aluminium, so excessive wear is obviously not an immediate issue, or there would be a lot of comment all over the NET to steer away from them. Of course, an aluminium cover doesnt preclude the use of them per’se, oil pressure gauges give us a dynamic indication of oil pressure, so as the cover plate wear issues will no doubt result in less oil pressure. Ironically, I think particles suspended in the oil will probably cause more scratching/grooving and accelerated wear in the plates, so decent filtered oil becomes another good reason as to why you might want to consider filtering your oil! It is, nevertheless, a valid point that needs thinking about, so thank you for that.

What is more important to me as far as your post is concerned is the fact you can get pressure-relief cover plates. Reading up some more on these however, they sound like they dump oil back to the suction side of the pump(?). There are quite a few warnings out there that the relief valves have a tendency to stick and come with an engine health warning, so clearly they look like that they have their issues too and you run some pretty potentially high risks to your motor if this happens…so clearly more homework needed by ‘yours truly’ before I consider this route.

tps8903

Ok, in answer to your perfectly sound logic about VW Engineers…yes they knew their beans for the technology of the day, certainly without doubt, light-years beyond me. However, it is an old design, really old, as is many other aircraft motors out there that you mention, most of which were also designed in the 1930’s. During the 60’s and 70’s there were some in-depth studies into the benefits of filtration and the results were clear. Since the lessons of those studies, ALL engines today are designed with far better oil filtration, with the proof of the VW pudding being that the Boffins at VW decided that the Type 4 was to have an oil filter fitted as standard.

So the longer term benefits are clear on that score (I have a conversion kit on my soon to be supercharged 1934 MG OHV engine, which also relied on a wire gauze filter). Neither am I questioning John Monnett’s wisdom, but the fact he offers after-market kits in the form of the Maxi sump filter units, in itself means they consider it important enough to at least offer the option (my engine came with a brand-new Maxi-sump filter kit BTW, so that’s an option open to me too). If that wasn’t enough, Revmaster (who IMHO made a more refined engineered engine) fitted their own proprietary high-volume oil pump bypass filter system, so again, another endorsement to giving the issue (on more than one level) very serious consideration, which in my opinion, backs up the fact that if you want to get the best out of an engine in terms of long-term reliability, then effective oil filtration is a no-brainer.

Also in answer to your other point…I think you have a typo, but I think I know what youre driving at…. If you are running the engine without an effective particulate oil filter, oil changes need to be MORE regular (not LESS as you state) if you want to ensure that levels of contamination remain as low as possible. No doubt that’s the main reason as to why Sonex recommend changing the oil every 25 hours, because they are working on the assumption that the vast majority of engine kits sold will never get a fine particle filter fitted(?). Trouble is regular oil changes do not stop metal particles from being transmitted around the system multiple times causing ongoing scoring of big-ends etc and the onset of premature wear…which brings me back to my point regarding long-term reliability…..

Bryan

Quote: “Also regarding adding flow with a 30mm pump - why?” Good point in which I hadn’t really explained the thinking, so my bad. Of course, volume and pressure are two different beasts. I have read (and indeed have been told by a VW shop) that one of the short-comings of the bolt-on, all-in-one pump/filters is that they do not pump as much volume as the conventional system as the oilways are restrictive(?). I made the statement for because I don’t know if the higher capacity pumps have bigger oilways, to and from the pump-cover, to filter? Of course Sonex push these engines out to 2100 CC so a bigger pump isn’t necessarily a bad idea, especially if introducing more restrictions in the system such as an Oil Filter, Oil Cooler, etc and you don’t want to drop main-bearing pressure, but the point still stands that Sonex have decided that the 26 mm gear is more than adequate (and more likely to take less energy from the engine to drive). As I haven’t seen one of the EMPI pumps in my hot little hand, I don’t know if they can be used with the standard Sonex 26mm pump that comes with the Aerovee kit? (I don’t see why not?).

So to summerise….

Area 51 is quite relaxed about his experiences with his oil-filter unit and indeed would fit another

Steel to aluminium wear of oil pump gears…worth considering, however I haven’t found any other references to accelerated wear issues on other forums etc. It suggests that it is not an issue that causes regular concern (and as Area 51 quite rightly points out, is operating in the best lubricated environment of the entire engine anyway)

Pressure relief valves in oil-pump covers, need more investigation (by me) as to where they by-pass excess oil pressure to. This may be as crucial to the integrity of the engine and warnings suggest that they could be as catastrophic to the engine as a blown gasket/filter. If this proves incorrect, a more conventional full-flow system (drilling the case) may be a better way to go despite the introduction of extra weight and complexity of introducing more pipe connections

That the benefits, as opposed to drawbacks, of particulate filtered oil is largely down to one’s personal opinion and understanding of what you are trying to achieve in terms of longevity/reliability of your engine and how you value the associated risks vs complexities

In terms of “whatever helps you sleep at night,” the minimum I would sleep with is, at worst, fitting the unused Mini-sump kit that came with the aircraft. At best, a better “spin-on” filter on the pressure outlet side of the pump…along with a properly set up and BALANCED bottom end (but that’s another story)….

Re: EMPI Full-Flow High Volume Oil Pump and Filter unit

Posted: Sat Dec 02, 2023 4:44 pm

by Area 51%

As an afterthought, the Mexican built VW Beetles came with a spin-on oil filter attached to the oil pump. Hmmmmmmmmmm

Re: EMPI Full-Flow High Volume Oil Pump and Filter unit

Posted: Sat Dec 02, 2023 5:55 pm

by Hap Hazard

Area 51% wrote:As an afterthought, the Mexican built VW Beetles came with a spin-on oil filter attached to the oil pump. Hmmmmmmmmmm

Interesting…do you know what form they took A51? Were they the more traditional remote filter plate or the EMPI-style combo unit I refer to in my thread?

On the subject, it is interesting to note that the Mexican engines had a high-capacity pump fitted to a 1600 cc engine…

From US Archive.org, quote:

A full-flow filter pump is used with larger (30mm) gears for higher oil flow. This provides

better filtering to avoid fouling the hydraulic lifters. Because of the higher oil flow, pressure is

better maintained in hot climates. Factory spec oil is 15w40 for the Mexican climate range; but

in a wider temperature climate a 5w40 or 0w40 synthetic is more appropriate. The 70s dual

relief oil pressure control is used. The spin-on filter is the same as used by most water-cooled

VW 4-cyl engines, and the anti-drain back of the Vanagon waterboxer filter (070 115 561) is

helpful. (OEM are Mann or Mahle brand, available from busdepot.com.)

HH

Re: EMPI Full-Flow High Volume Oil Pump and Filter unit

Posted: Sat Dec 02, 2023 6:34 pm

by Area 51%

Hap Hazard wrote:Interesting…do you know what form they took A51? Were they the more traditional remote filter plate or the EMPI-style combo unit I refer to in my thread?

Not sure who copied who…but the Mexican pump/filter assembly and the Empi would be hard to tell apart at 20ft.

Re: EMPI Full-Flow High Volume Oil Pump and Filter unit

Posted: Sat Dec 02, 2023 6:43 pm

by Area 51%

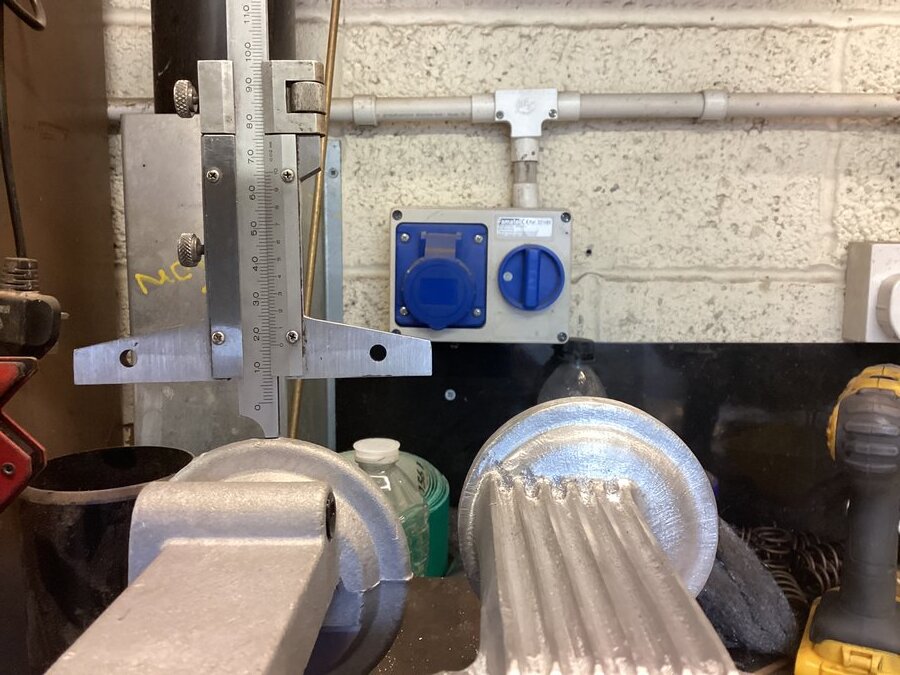

This is how much cowl had to be removed to clear the filter assembly.

Re: EMPI Full-Flow High Volume Oil Pump and Filter unit

Posted: Sat Dec 02, 2023 7:12 pm

by Hap Hazard

Hmmm…a lot needs cutting out then… Great posts A51, you have been a brilliant help in giving me a better idea of what I am up against in terms of fit.

Much appreciated ![]()

Re: EMPI Full-Flow High Volume Oil Pump and Filter unit

Posted: Sun Dec 03, 2023 8:00 pm

by BRS

I wonder if the RevMaster oil pump would work on that engine. Mine fits nicely under the cowl.

Google ‘Revmaster R2300’ and check out he images

or…

https://s28490.pcdn.co/wp-content/uploa … ptimal.jpg

Re: EMPI Full-Flow High Volume Oil Pump and Filter unit

Posted: Sun Dec 03, 2023 8:43 pm

by Bryan Cotton

That Revmaster prop shaft looks a lot longer than the Aerovee.

Re: EMPI Full-Flow High Volume Oil Pump and Filter unit

Posted: Sun Dec 03, 2023 11:28 pm

by BRS

Yes, you are correct. But the cowl was not modified where the oil pump goes. You can see I lengthened the area around the crank up to the prop. The oil filter is that shiny bit in the right air cooling inlet.

The bump above the intake snout is for the corner of the oil cooler. BTW - I’ve not been able to use the intake snout external air with the RevFlow/AeroInjector TBI’s but was recently told by Rotec that this would work fine with the MKII. Looking forward to trying that.

Re: EMPI Full-Flow High Volume Oil Pump and Filter unit

Posted: Mon Dec 04, 2023 6:24 pm

by BRS

BTW - here is a pic of the Revmaster pump/filter setup.

Re: EMPI Full-Flow High Volume Oil Pump and Filter unit

Posted: Tue Dec 05, 2023 6:47 pm

by Hap Hazard

Thanks for the post BRS.

Personally I think the Rev Master is the better engineered and developed motor than the Aerovee. If I were building a Onex kit, I think I would definitely go for the Rev Master over the Aerovee (if I stayed with the VW route) due to it being more of a quality build, with lighter H-section rods, a decent oil filtration system, beefed up front bearing and no doubt a better balanced rotating mass down below (my pistons from Sonex are well out!). What’s hiding in that shiny “beehive” cover on your remote oil filter plate? It looks beefy, are you running a Canton type oil-filter inside that fancy thing? I bet the oil-ways in their remote filter casting are bigger too. Rev Master really did think of everything (and obviously valued the benefits of filtering the oil) and developed the VW to its zenith as an aeroplane engine.

I might get a a EMPI-style CB casting anyway as I am looking to do a few mods to my exhaust etc and may even make a custom engine cowling (which will allow me to work around the filter etc) as I am looking to put a high pressure duct over the sump (looks like you have done something similar or it simply the oil-cooler bracket?) but this duct will need to be fully enclosed and carefully engineered so as not to pressurise the low-pressure side of the cowling. I am also looking to install a duct for ram air to the inlet of the Aero-injector carb as well

Just out of interest, does your oil filter and oil-cooler bracket have a fuel-pump drive off the other end and is that connected to Revflow carb? Of course the Aerovee is purely gravity fed, but I read that fuel “burping” is a regular issue…(I will look to install a burp tube in mine whilst I have the engine out).

Cheers,

HH

Re: EMPI Full-Flow High Volume Oil Pump and Filter unit

Posted: Tue Dec 05, 2023 11:09 pm

by BRS

The oil filter is from K&P https://kandpengineering.com/product/s15/. I started using Napa Gold filters on my IO-360 in the Sportsman years ago then I came across these. So I’m now running them in the Sonex as well. Tired of spending $50 just for an oil filter. So far, I’m very impressed. They also have a certified version for those wanting to spend on it (same filter). Very, very easy to inspect and clean the filter element.

The ‘pressure duct’ under the sump is needed because the oil cooler is there below. I’ve done my best to seal it all up since it does dump in the bottom of the cowl reducing air pressure differential. After modifying the cowl with an RV-6 snout I soon learned that ram-air into the RevFlow/AeroInjector TBI’s does not work. But since installing the Rotec MKII they have said that my ram-air should be fine. I’m assuming it’s because of the regulator and that the spray bar works more on low pressure created over the spray bar. So, I’m in the process of unblocking the ram and fashioning a filter solution for it.

No fuel pump - strictly gravity.

Re: EMPI Full-Flow High Volume Oil Pump and Filter unit

Posted: Tue Mar 26, 2024 5:25 pm

by Hap Hazard

Hi All, to wrap this one up, here’s an interesting post that might help future decisions on which spin-on oil filter kits to go for.

Originally I had obtained a certain product (whom wouldn’t talk to me after I mentioned aircraft, but weirdly looks like some of their stuff looks to be supplied with my engine) and I decided to “flow the galleries” more and actually widen them out a bit. As the casting felt pretty heavy, I lightened it up by taking off some of the casting along the beefy body and took a little more weight out by making the cooling fins run full length of the casting. All-in-all, I managed to shave off around 7.5oz and got it down to around 17 oz.

Shortly after I looked at the EMPI product again and contacted EMPI as I was unsure what the casing was just behind the spin-on filter itself. I assumed it was probably some sort of by-pass valve if the pressure across the filter got too high. Obviously this would be a far more worthwhile feature if my assumption was correct as it would help in preventing blowing the filter sealing ring out and dumping all the oil. So I contacted EMPI for more details.

Yes, I was correct, it is a Bypass valve. The spring inside is set to bypass the filter when oil pressure in the supply line reaches 95 psi and dumps the oil directly into the pump-return line.

So here’s the findings between the two:

EMPI:

Pros: by-pass valve (a must for our application)

Better quality casting

Offset of spin-on oil filter sits 5/8 inch further back from prop boss (see photo of two brands)

Much lighter casting (weighed without pump or filter) at 16.4 oz’s.

Cons: slightly smaller oil galleries with some obvious restrictions on 90 deg bends

Cannot bore out galleries

Casting flashing which restricted flow on supply gallery

Other, “well-known” brand

Pros: easy to bore out gallery size

More easily to flow bends

Cons: no safety by-pass valve

Heavy at 25 oz

Poor quality casting despite generally excellent reputation for high-end VW aftermarket parts

Clearly the EMPI product is the one to go for, lighter, better quality (despite being made in China, which to be fair, probably both were). I removed the by-pass valve and spring and removed any casting flashings and removed any sharp bends by flowing the galleries where they abruptly changed direction. Flushed system out to remove swarf from my die-grinder.

Hope this helps in choosing which spin-on kit to go for?

Extra info, pump size on the EMPI product is huge, with 32mm gears, whereas other brand, was 26mm gears (same size as Standard Sonex Aerovee size pump). I may try fitting the 26mm geared bypass pump first and see how that goes?

Re: EMPI Full-Flow High Volume Oil Pump and Filter unit

Posted: Fri Mar 29, 2024 11:44 am

by karmarepair

I’m having a little trouble parsing your last sentence, but I think what you’re saying is you’re going to try the EMPI cover/filter with the bypass valve on a 26mm pump.

If so, I like this idea.

I have always been skeptical of these filter/pumps; knowing the EMPI unit has a bypass makes me more likely to try one.

Re: EMPI Full-Flow High Volume Oil Pump and Filter unit

Posted: Sat Mar 30, 2024 6:54 am

by Area 51%

Be sure to map-out the passage holes on the cover versus the holes in the body. They don’t always match up with different brands of pumps. I had to elongate the hole in one to match the hole in the other.