I have a bunch to post on this topic, But working out picture posting, so I’m going to start off small.

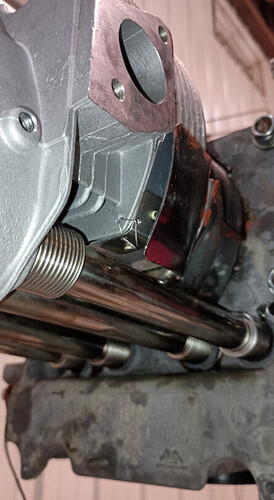

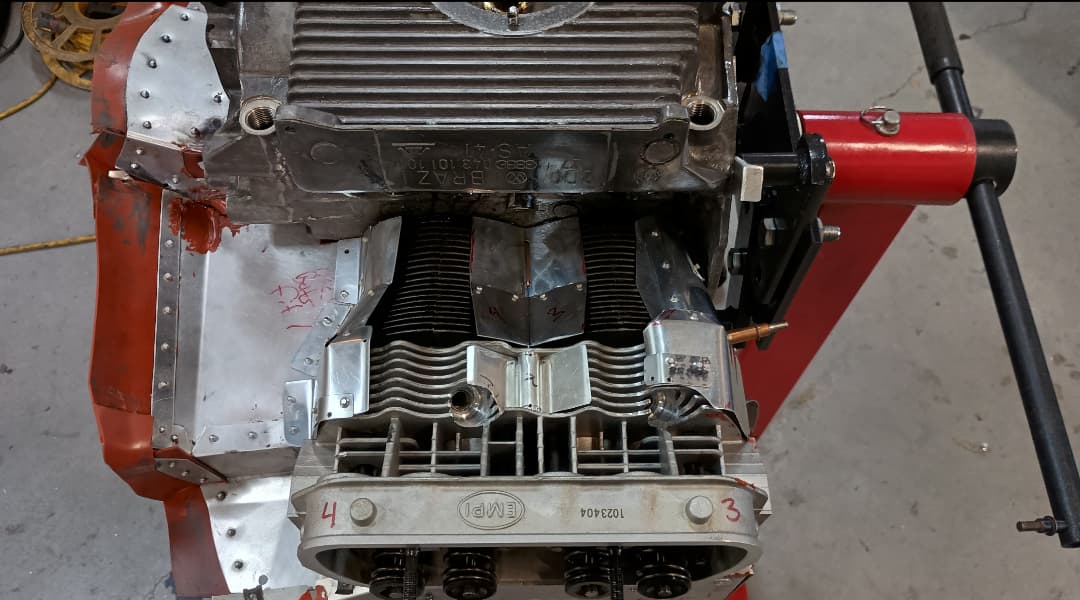

Here is a picture of the super tin and how crappy of a job it does forcing the air around the heads, front and rear.

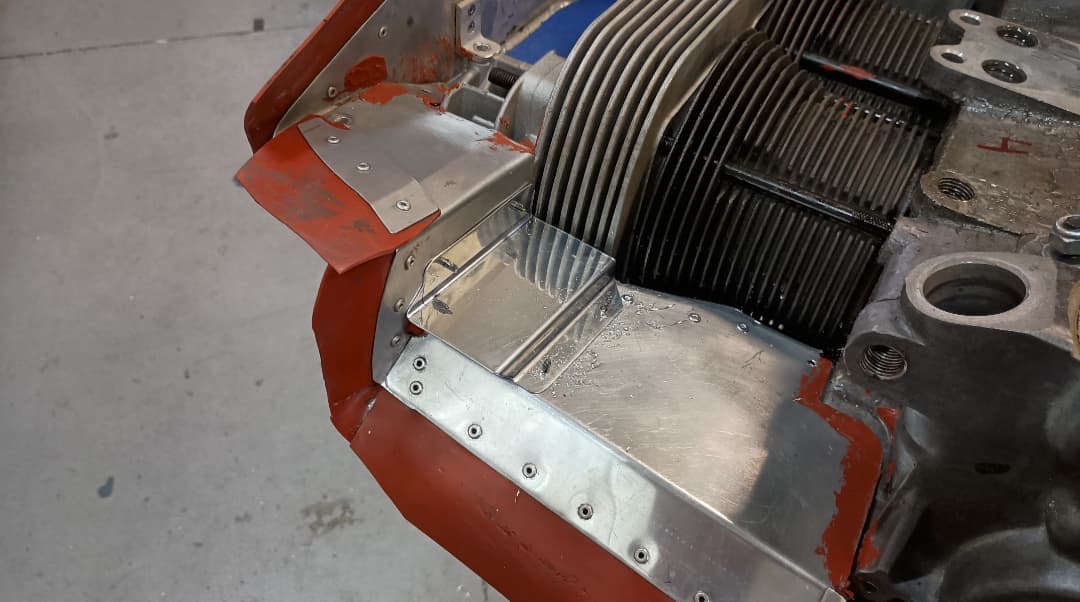

So in this next picture, I’ve made a baffle that forces the air through the fins, and makes it turn the corner and exit through the bottom cooling fins.

I drilled a hole in the cooling fins, and riveted a little piece of stainless to my corner baffle so I could safety wire it in place. The main baffle tucks both into the super tin and my new baffle so the air gets directed only through the cooling fins, and without the leak that the super tin has.

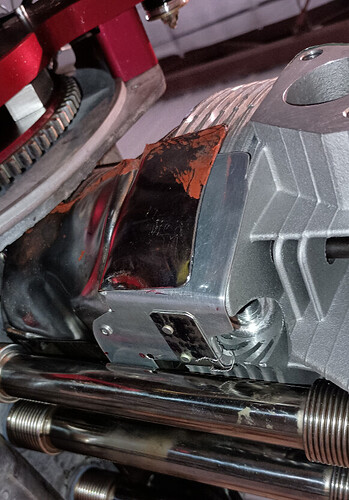

Here is the right rear baffle. Note that this is just a rectangular piece of metal, same width as the span of the cylinder head cooling fins. I have bent it to shape, and clearanced as required to miss the spark plug holes and also the exhaust outlet boss. Again I have a piece of stainless for safety wire. In this iteration the super tin captures the other side against the head.

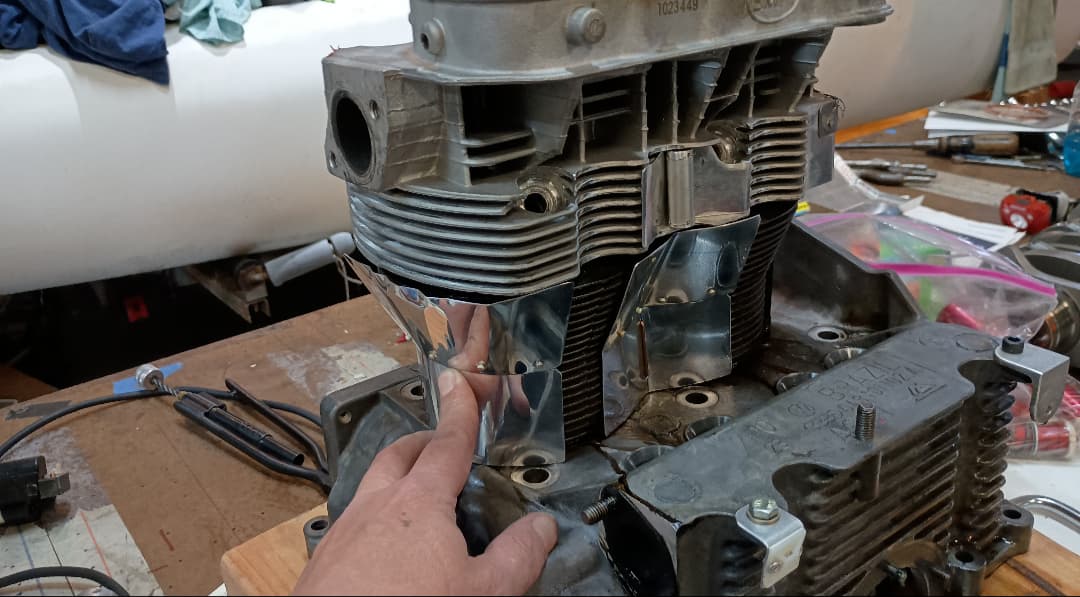

Here is the space between the cylinders, after I cleaned up the casting. A bunch of air goes down there but really does not do much. It doesn’t go through any cooling fins and once it gets out the bottom it is done cooling.

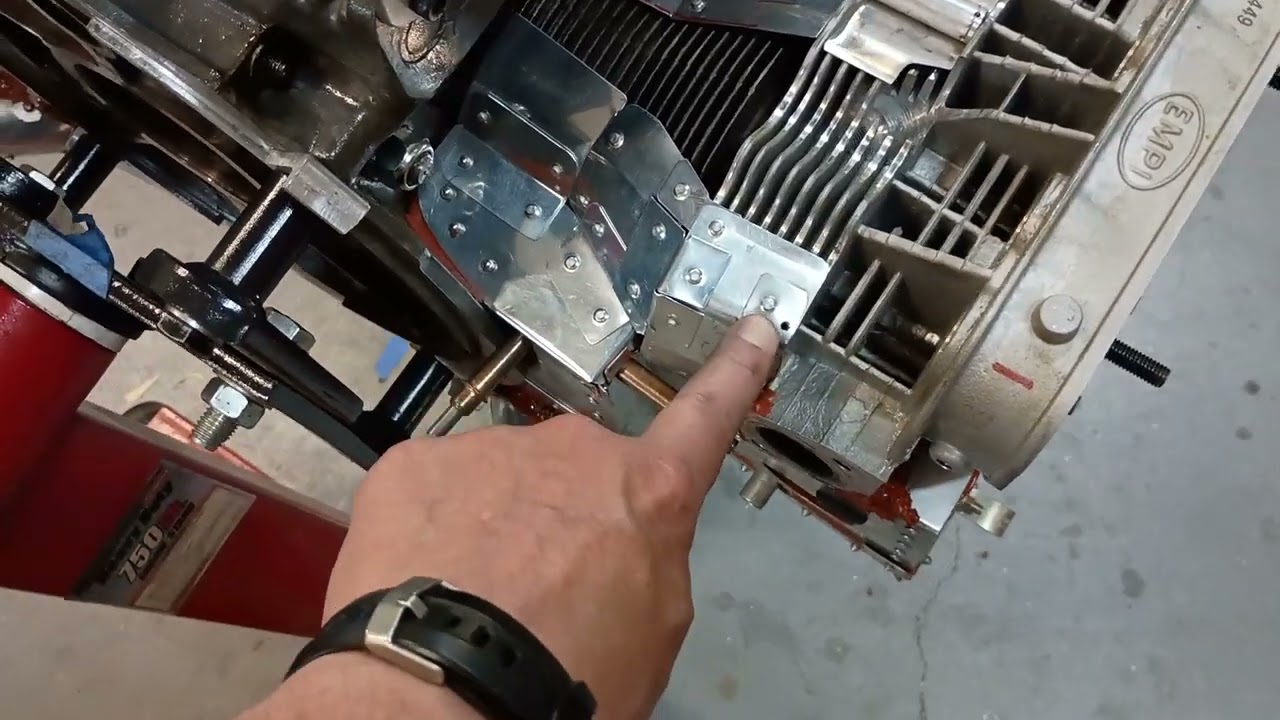

That picture is from the top. I made this baffle, basically a V shape that goes in the valley of the inter-cylinder gap. I used an aluminum tube with safety wire to secure it.

Here it is installed from the bottom.

On top I’ve drilled a couple of holes in the cooling fins for the safety wire.

I was going to post the picture here but am still figuring out picture limitations. The key thing is the air coming down through the slot now divides, and goes fore and aft through the cooling fins.

So I’ve decided I don’t like the super tins that much. Mostly because there are a lot of air leaks, up at the head where it is critical and down on the cylinders which should not need as much cooling as the head. Plus I put on a big spring loaded pushrod tube to fix a leak (success) but I had to hack the super tin for clearance. Later I changed all my pushrod tubes to that type (which will be another post sometime) and the super tin hack-a-thon was intense. And I still had some interference. But back to cooling - I felt like I could make an aluminum baffle that would do a better job and be lighter. The jugs are basically cylindrical on the bottoms, and a conic section on the top. I played around with paper and came up with some patterns, and started making pieces.

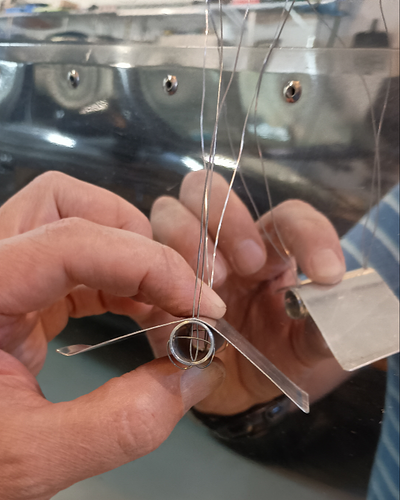

The inter-cylinder baffle was a little tricky. Made the pattern in paper and then the real parts. I made a “staple” out of welding rod which will be used to safety wire the baffle into the valley. It will attach to the studs on the top side.

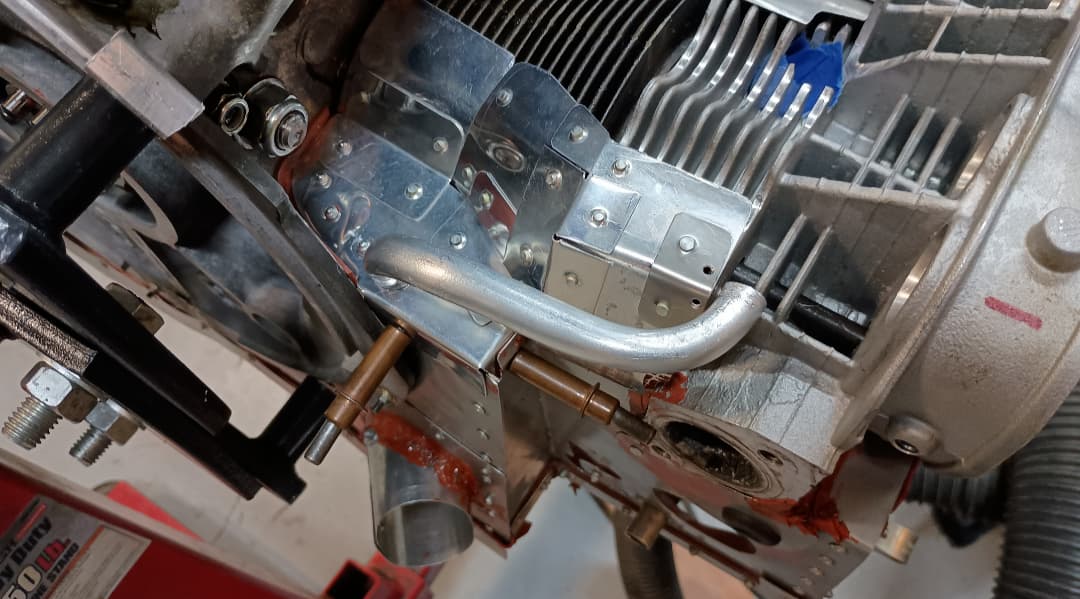

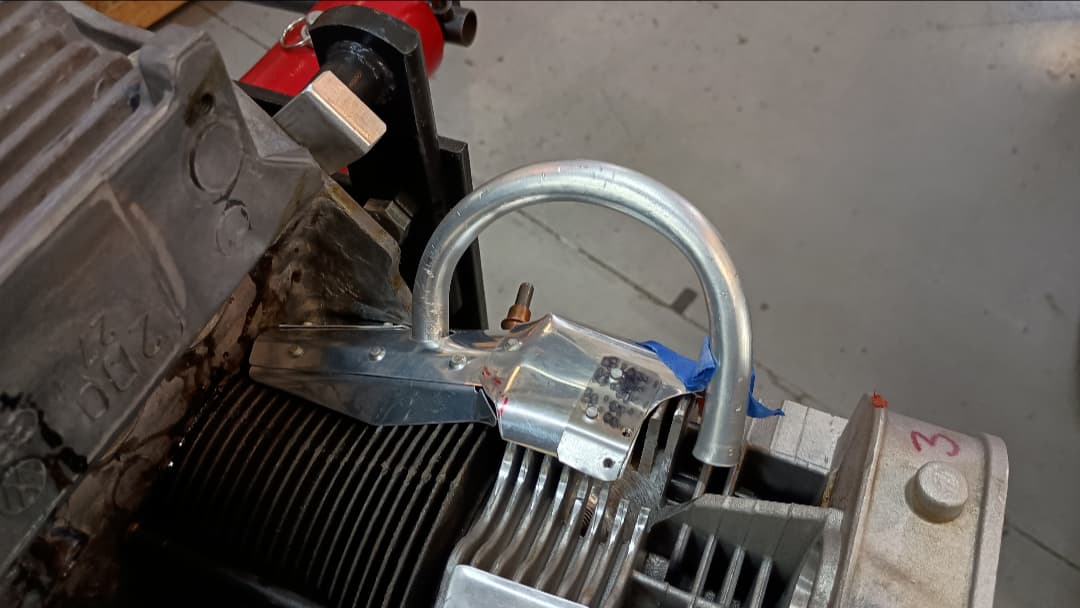

I remade my corner head baffles to be a little wider, and to rivet to the cylinder baffles. That was sort of tricky because the head baffle is rectangular, and the cylinder is circular. But with some creative bending and cutting, I got it done. Here is #3.

I totally redid the #1 corner. I never liked what I had before. Here is the removable piece, it will be pop-riveted on after the rest of the baffles are in place. I’ll use aluminum pops to make it easy to drill out later.

Here it is installed.

I was able to rivet the front corner baffles to the original front baffle, and I can still remove and replace it. Here is #4.

And one more thing - this saves about 1 lb of weight as compared to the super tins.

My #4 cylinder, right front, has been the hottest especially during climb. I’m thinking that the ramp on the front baffle and the prop going up on that side make the air go up and over the cylinder. I talked to another Waiex builder/pilot and he observed the same thing. So I made this little scoop for #4:

Head on view:

I forgot to post the video I did.

I’ve added blast tubes to the back cylinders, where the heads get no air.